搜索

Number of views:

1000

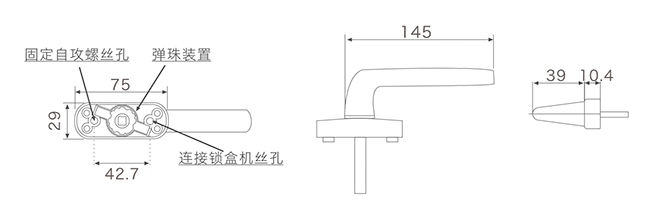

JLM-B160 Handle with rectangular handle

Surface treatment: electrolysis

Material: titanium magnesium alloy

Configuration: square axis / Nylon base

Product serial number

Retail price

0.0

Yuan

Market price

0.0

Yuan

Number of views:

1000

Quantity

-

+

Stock:

Website's Pic when there may be error,and the actual product color and the shape of the differentspace, area and the light also can produce different colour deviation, correct color please refer to our actual product.

1

Describe

Parameters

Detailed introduction

Specification parameters

Color: Mirror sapphire, mirror deep bronze, mirror pearl silver

Surface treatment: electrolysis

Material: titanium magnesium alloy

Configuration: square axis Nylon base

Surface treatment: electrolysis

Material: titanium magnesium alloy

Configuration: square axis Nylon base

Handle usage and precautions:

1) Take out the handle cover from the base, rotate it 90 degrees, put it in the middle, and expose the machine wire connection lock box hole and self tapping screw hole;

2) Insert the handle into the front aluminum hole, adjust the angle of the lock box, and insert the square shaft into the lock box;

3) Pass the machine wire through the lock box hole and connect it with the lock box body machine wire hole (or sliding block). When connecting, don't tighten it too tightly. The lock box transmission should be the smoothest, so as to avoid pulling the lock box and causing unsmooth opening (six hole design, the handle is not fixed by the machine wire, but self tapping screw)

4) When it is connected with the sliding block, it can be screwed to the most tight position, and the lock box and handle will not be loosened (generally, it is recommended to use self tapping screw instead of self drilling screw)

5) Then use self tapping screw to fix the self tapping screw hole, tighten the screw diagonally, and fix the handle on the aluminum surface;

6) After the screw is installed, adjust the switch handle, adjust the tightness of the two long wires of the lock box, and adjust the lock box to the most smooth;

7) Return the handle cover to its original position and cover it well (Note: when installing the screw thread, the air driver should avoid damaging the lock cover as much as possible)

8) Before the door and window are delivered to the owner for use, please do not tear off the protective plastic film or plastic sleeve on the handle to avoid scratching( Pay attention to the tight handle when locking and closing the window. Please adjust the position of the core pin to achieve smooth switching and prolong the service life of the lock box and handle!)

2) Insert the handle into the front aluminum hole, adjust the angle of the lock box, and insert the square shaft into the lock box;

3) Pass the machine wire through the lock box hole and connect it with the lock box body machine wire hole (or sliding block). When connecting, don't tighten it too tightly. The lock box transmission should be the smoothest, so as to avoid pulling the lock box and causing unsmooth opening (six hole design, the handle is not fixed by the machine wire, but self tapping screw)

4) When it is connected with the sliding block, it can be screwed to the most tight position, and the lock box and handle will not be loosened (generally, it is recommended to use self tapping screw instead of self drilling screw)

5) Then use self tapping screw to fix the self tapping screw hole, tighten the screw diagonally, and fix the handle on the aluminum surface;

6) After the screw is installed, adjust the switch handle, adjust the tightness of the two long wires of the lock box, and adjust the lock box to the most smooth;

7) Return the handle cover to its original position and cover it well (Note: when installing the screw thread, the air driver should avoid damaging the lock cover as much as possible)

8) Before the door and window are delivered to the owner for use, please do not tear off the protective plastic film or plastic sleeve on the handle to avoid scratching( Pay attention to the tight handle when locking and closing the window. Please adjust the position of the core pin to achieve smooth switching and prolong the service life of the lock box and handle!)

Keyword:

handle

the

and

lock

box

to

screw

it

hole

contact information

Business Consulting:

Mr. Ding 133 8025 9489

Miss Yang 189 2728 9996

Email: 2410096915@qq.com

Asia Pacific Office: room a25, 8 / F, Silver Tower, 707-713 Nathan Road, Mongkok, Hong Kong, China

National Service Hotline: 400 8336 822

Copyright © 2021 All Rights Reserved Foshan Nanhai Dali xiongtao decoration materials firm 粤ICP备15098155号 300.cn